Active Efficiency in Action

The best way to understand the value of Active Efficiency is to see it in action. There are many examples that demonstrate the potential of Active Efficiency. Between the economic, social, and environmental benefits, the hard work that goes into making these examples successful is something to be celebrated.

Strategic Energy Management at Bonduelle Fresh Americas

Bonduelle Fresh Americas, one of the nation’s largest produce distributors, set out to reduce energy usage across its portfolio as part of its corporate responsibility plan. Its plant in Irwindale, CA, however, had already picked all the low-hanging fruit in traditional energy efficiency (e.g., adjusting operating schedules of high-energy consuming equipment). To drive 5% in further savings, in 2018 Bonduelle joined one of the first cohorts of the Strategic Energy Management (SEM) program offered by California investor-owned utilities, including Southern California Edison (SCE). The program encouraged the adoption of an Active Efficiency approach to energy management and led to more than one million dollars and 8 million kWh of savings at the Irwindale plant as it developed a more robust energy management system.

An energy management system is a process for tracking and improving energy use. Digitalized tools can support energy management by bringing together granular data from energy-using devices in a building then generating intelligent, specific, real-time guidance on how to optimize consumption to capture the most compelling savings. The system integration and time-dependent perspective that the digital tools bring to an energy management system exemplifies an Active Efficiency approach. To encourage this approach, California’s Public Utility Commission and the state’s investor-owned utilities jointly developed a SEM program design and measurement and verification guide to offer to recruited industrial customers.

Taking a multi-pronged approach to energy management

The SEM program targets high energy consumers in the industrial sector (reflecting a diversity of business operations) and invites them to join a cohort to learn how to develop energy management systems. In the first year of the program, companies work to establish sound energy management system practices and implement organizational and operational changes to save energy at their facilities. SEM spurred Bonduelle to put key structures in place across the plant and the corporation. A cross-functional energy team meets every month to review technical projects, savings from implemented projects, and plant-wide engagement. The monthly reviews feed into a quarterly update to senior management on progress to-date, so that they can see how resources and practices are contributing to success. This in turn sets an example across the corporation, enabling plants to compete and collaborate on achieving energy savings.

During the second year, participants solidify and advance those practices. Throughout the process, SCE and the implementer, Cascade Energy, coordinate closely to proactively engage the customer and provide them with the technical assistance needed to bolster their energy management practices. Even accounting for the robust technical support, the program is highly cost-effective: The total resource cost (TRC) ratio for the entire SEM program at SCE in 2019 was 4.3. The cost-effectiveness of the SEM program has sustained its success despite the economic challenges associated with the COVID-19 pandemic; Cascade Energy has adapted from in-person to virtual workshops to avoid implementation delays and SCE forecasts a TRC of 2.55 in its 2021 annual budget advice letter filing.

The SEM program offered exactly what Bonduelle’s Irwindale plant needed: a toolkit to deepen its energy savings. The plant joined one of the first cohorts beginning in July 2018. According to Albert Buffa, Technical Manager of the plant, his team quickly gained greater insights; through an initial energy mapping exercise, the plant decided to focus energy efficiency measures on its refrigeration system, such as ramping down the ammonia compressors on days the plant was not running after learning the system consumed 65% of the facility’s total energy. The plant also held multiple treasure hunts through the SEM program, identifying energy saving opportunities and generating 61 total energy efficiency projects, 39 of which were completed in the first two years.

How software tools can support energy management

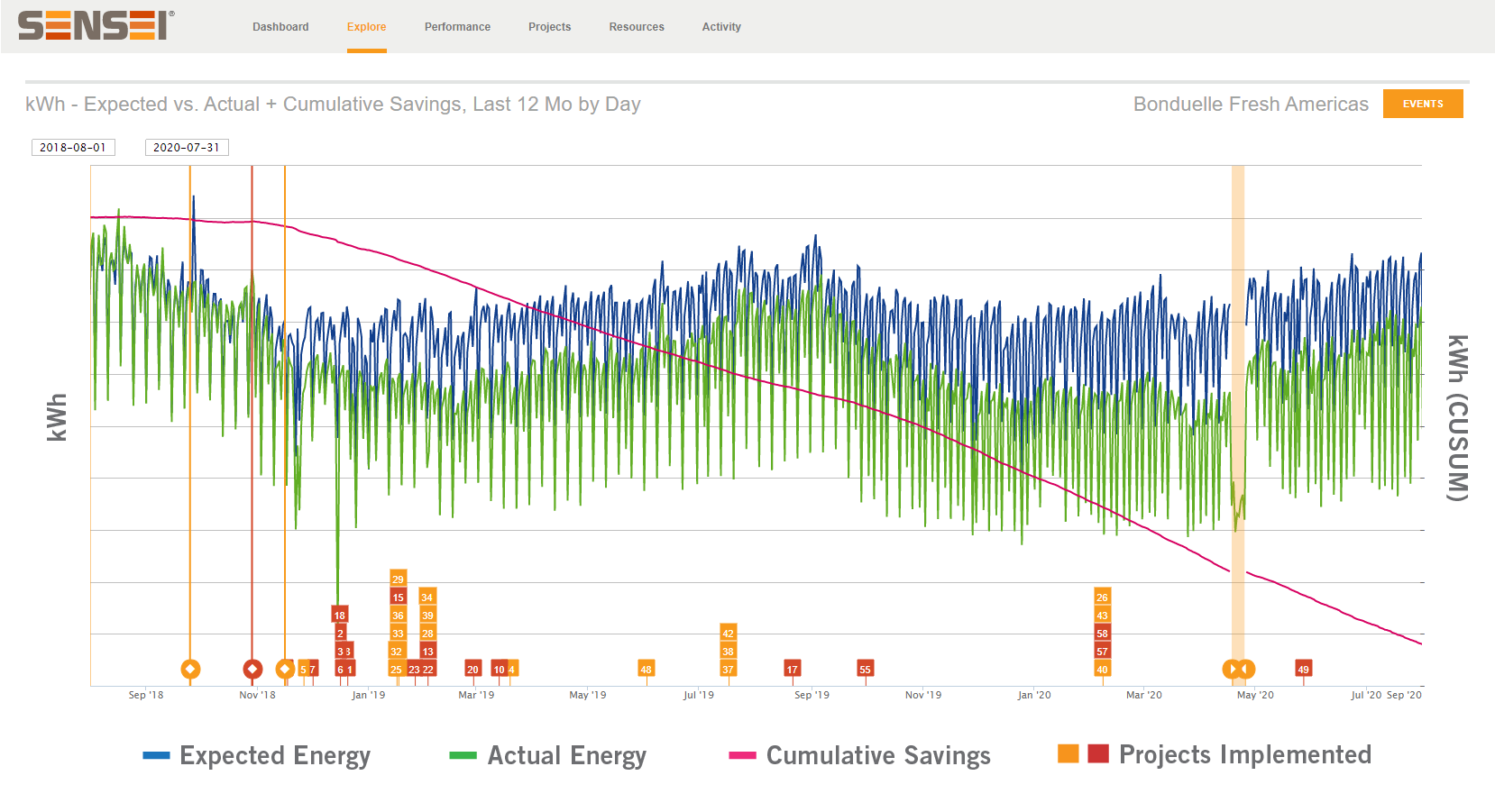

In addition to conducting the energy mapping exercise and completing the energy efficiency projects, the program encouraged the use of software tools to support energy management and energy modeling. The Bonduelle Irwindale plant uses a proprietary software tool called SENSEI®, offered by Cascade Energy, to conduct analysis on energy use and to track the schedule and impacts of energy efficiency projects. SENSEI helps operators track measured savings, project progress, and results in coordination. The Bonduelle Team uses SENSEI® in two key ways: first, they use the tool to ensure plant-wide monthly savings are on track, and second, they assess if energy projects delivered on their potential. As shown in the below screenshot, SENSEI® shows Albert and his team how the plant performed so they can get back on track if there’s any backsliding. SENSEI® also aligns projects and savings on the same timeline so the Bonduelle team can see quickly if bigger projects are having the impact expected.

Figure 1. Monthly savings as percentage of baseline energy consumption at Bonduelle’s Irwindale plant, as displayed in SENSEI®

The impacts

The SEM program benefits both the utility and the Bonduelle Irwindale plant itself: By reducing its energy consumption during SCE’s 4 p.m. – 9 p.m. period of peak demand, Bonduelle reduces stress on the grid, therefore helping SCE avoid costly grid infrastructure expansion. And since joining the SEM program, Bonduelle’s Irwindale plant has saved more than one million dollars and at least 8 million kWh, the equivalent to removing more than 1,200 passenger vehicles off the road for one year. Thanks to the success at the Irwindale plant, Bonduelle is taking this Active Efficiency approach to its facilities across the country, enabling greater energy and cost savings for years to come.